What is the raw material of welded steel pipe?

2019-01-14 11:00:10 Hits:

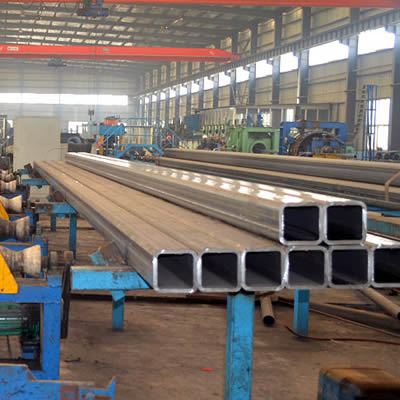

Hot rolled coils are made of slab (mainly continuous casting slab) as raw material and heated by roughing mill and finishing mill. The hot strip from the last finishing mill is cooled by laminar flow to set temperature, and coiled into strip coil by coiler. After cooling, the strip coil is processed by different finishing lines (leveling, straightening, cross cutting or longitudinal cutting, inspection, weighing, packaging and marking) according to the different needs of users and becomes the product of steel plate, flat coil and longitudinal cutting strip. Because of its high strength, good toughness, easy processing, forming and good weldability, hot strip rolling products are widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries. The properties and application of product material Q235B Q235C Q235D Q345B SPHC 510L Q345A Q345E SS400 Q345G Q345F are introduced. Hot rolled coils are made of slab (mainly continuous casting slab) as raw material and heated by roughing mill and finishing mill. The hot strip from the last finishing mill is cooled by laminar flow to set temperature, and coiled into strip coil by coiler. After cooling, the strip coil is processed by different finishing lines (leveling, straightening, cross cutting or longitudinal cutting, inspection, weighing, packaging and marking) according to the different needs of users and becomes the product of steel plate, flat coil and longitudinal cutting strip. Because of its high strength, good toughness, easy processing, forming and good weldability, hot strip rolling products are widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries. With the maturity of new control technologies such as dimension accuracy, shape and surface quality of hot rolling and the appearance of new products, hot strip and hot strip products have been more and more widely used and become more competitive in the market.

Previous:Usage of High Frequency Welded Pipe

Next:What is the National Standard for High Frequency Welded Pipe

CHINESE

CHINESE ENGLISH

ENGLISH

Add: Shangdong Laiwu Gangcheng

Add: Shangdong Laiwu Gangcheng Email: lwsfy@lwsfy.com

Email: lwsfy@lwsfy.com Tel: 086-0317-5292656

Tel: 086-0317-5292656  Web: www.lwsfy.com

Web: www.lwsfy.com